CUT-UP SYSTEMS

Ready to run.

Frame Cut-up Systems are characterized by their self-contained structure with cutting modules and is delivered pre-wired with a control panel that is already mounted to the machine. Frame Cut-up Systems are easy to install and only require one power connection. The inline design easily lends itself to connect automatic transfer machines, which are often coupled with distribution lines for optimal cutting results and eliminates the manual hanging process.

LEADING TECHNOLOGY IN CUT-UP SOLUTIONS

Frame Cut-up System

All Frame Cut-up Systems are supplied with self-correcting magnetic Cut-up shackles to help prevent the shackles from miss-feeding when entering the Cut-up modules. The unique turning point and side plate configuration makes the machine easy to clean and flexible for future line modifications.

The stand-alone system requires minimal installation time because all the single point connections are integrated into the modules/machines. Frame Cut-up Systems can be used for Food Service applications and for Traditional Cut-up applications.

LEADING TECHNOLOGY IN CUT-UP SOLUTIONS

OPTI Flow Cut-up System

Foodmate flexible OPTI Flow Cut-up System can be controlled by advanced ChickSort weighing and InVision Grading Software to help optimize bird utilization based on weight and grade throughout the process effectively by increasing A grade pack out and increasing yield value throughout the entire process. The lines can be configured with by-passable bird unloaders and by-passable Cut-up modules.

Modules can be customized according to your processing needs. The system is able to handle all basic cuts, such as wings, breast, whole legs and drum and thighs with a speed of up to 6000 birds per hour on 12” centers and up to 7200 birds per hour on select cuts on 10” centers.

DESIGNED TO MEET ALL CUTTING REQUIREMENTS

Food Service Cut-up Systems

Food Service Cut-up Systems are designed to meet all 8 and 9-piece cutting requirements set by various fast food chains such as Popeyes, Church’s Chicken and Bojangles’.

This system can also be designed and customized to meet other food service cut-up requirements from different countries around the world, such as Korea (25-pieces) and Thailand. Foodmate has also supplied lines to make 4 and 6- piece bone-in breast cuts as well as 3 piece thigh cuts for school lunch programs in the U.S. Watch the video below to see a 9 piece Fast Food Cut-up System in action.

FOODMATE FRAME CUT-UP SYSTEMS

Compact Cut-up System

Leading Technology in Cut-up Solutions

Foodmate Compact Cut-up Systems are available in different configurations, designed to meet mainly traditional product mixes. Some systems are as simple as just cutting front halves and cutting leg quarters, while others may include wing segmenting, options such as weighing and whole bird distribution.

COMPACT CUT-UP SYSTEMS

Highly Customisable.

Available in different configurations

Each system is designed according to the plant layout and Cut-up needs. The systems are available in different configurations to meet variable product mixes. Some systems are as simple as just dropping front halves and cutting leg quarters, while other systems may have complex functionality to distribute product to different locations in the plant, based on weight range.

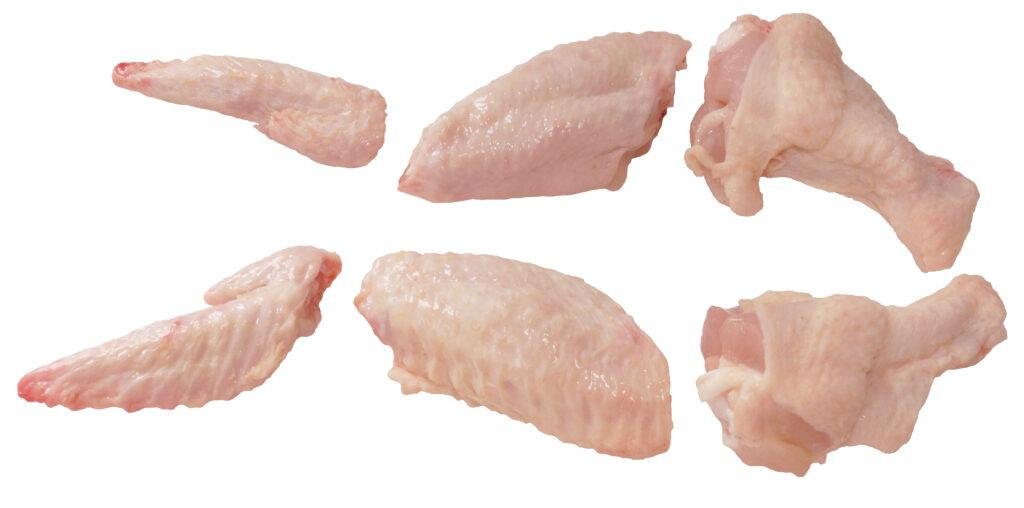

Wing Portioner

-

The Foodmate Wing Portioner cuts wings into two or three parts (drums, flaps, tips) and handles both broilers and roasters. This wing wheel will process left, right, and intermixed wings. Due to the unique design of the wheel and cutting blades, it operates efficiently at 50 – 60 wings per minute. The Wing Portioner is a compact machine that may be installed in a multiple unit system and has an optional three-chute slide that pushes the parts into a divided conveyor. It is composed of stainless steel and food approved nylon.

-

Allows for a maximum of 60 wings per minute

-

Stainless steel frame and motor

Motor (IP66) power is 0,18 kW

Machine dimensions:

– Length: 856 mm

– Width: 1294 mm

– Height: 1304 mm

– Weight: approx. 220 kg