FOODMATE CUT-UP MODULES

Excellent efficiency.

Foodmate provides solutions to meet the widest range of products specifications and cutting requirements, meeting the highest standards set by retailers, fast food companies and institutional organizations from around the world.

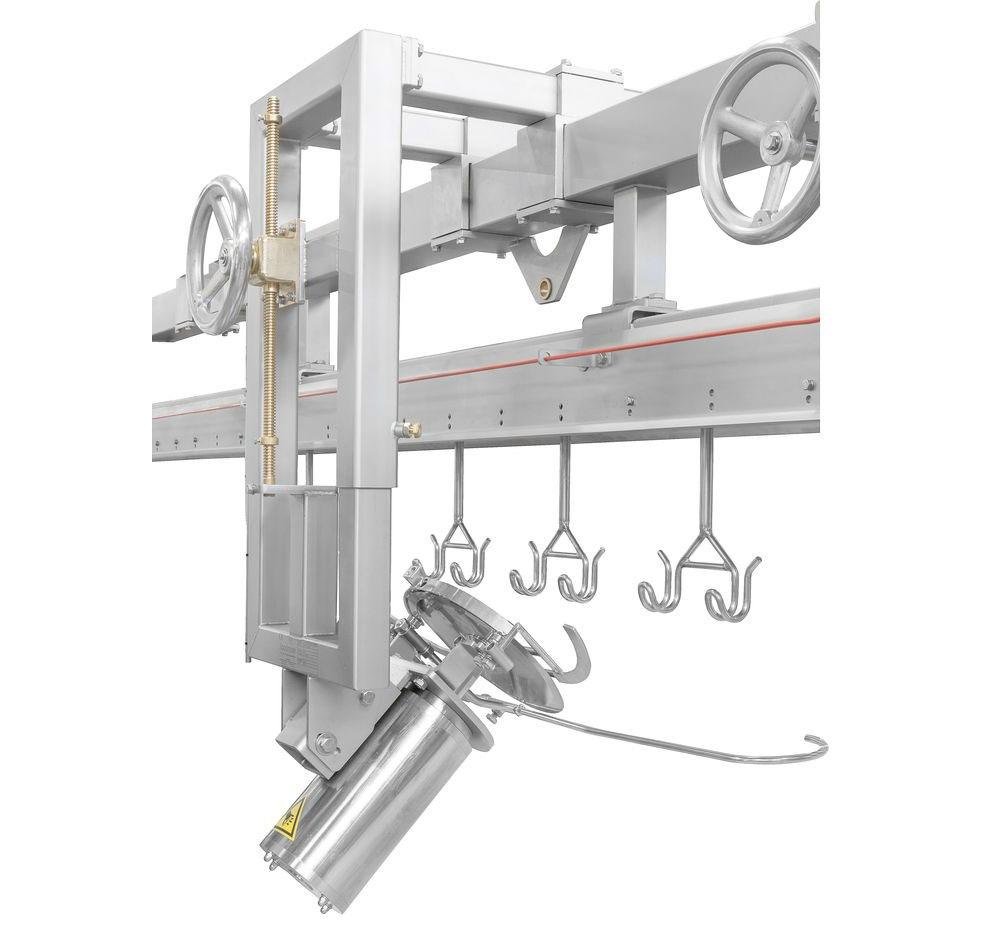

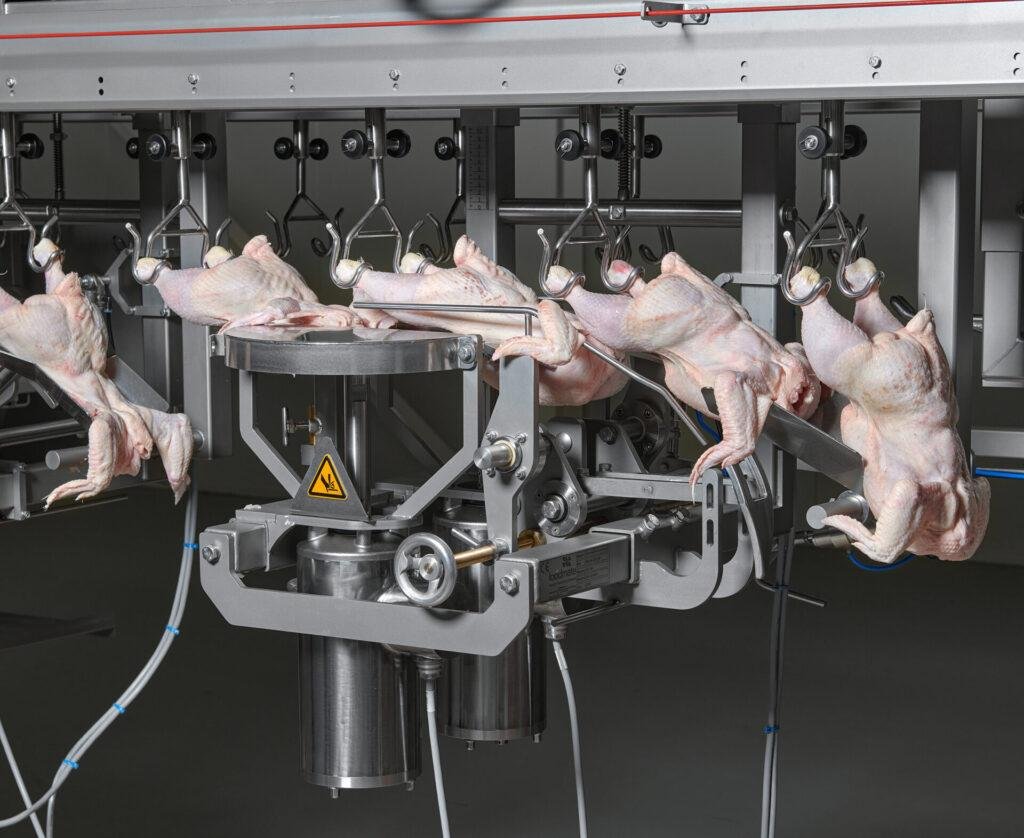

WING MODULE

Wing Stretcher

-

The Foodmate Wing Stretcher is designed to position and stretch the wings of the bird into the right position for the following machines to work properly.

When the bird approaches the machine, the bird is facing the machine breast first. A guiding rail positions the bird. Two other rails are placed in such a way that they will slide between the bird and the wings.

-

Allows for easy adjustment due to no moving parts

-

Stainless steel frame and motor

Machine dimensions:

– Length: 413 mm

– Width: 649 mm

– Height: 1224 mm

– Weight: approx. 30 kg

WING MODULE

Wing Tip Cutter

-

The Foodmate Wing Tip Cutter cuts the tip from the mid wing piece. The machine is developed to accommodate common bird sizes and gives an optimal yield on wing meat, while ensuring high cutting accuracy. The Wing Tip Cutter can be installed on current figurations or newly constructed Frame and Flex Lines.

-

Allows for a maximum of 6,000 birds per hour

-

Stainless steel frame and motor

Motor (IP66) power is 2 x 0,75 kW

Machine dimensions:

– Length: 754 mm

– Width: 1271 mm

– Height: 1304 mm

– Weight: approx. 140 kg

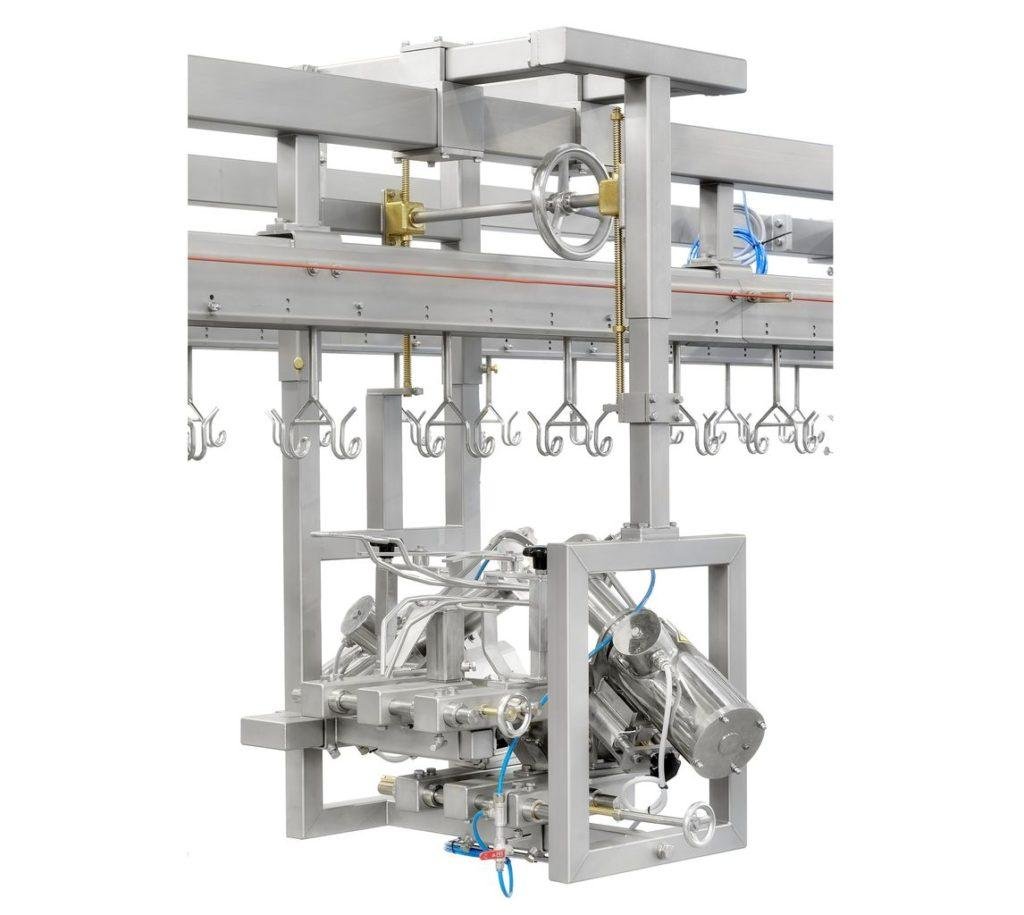

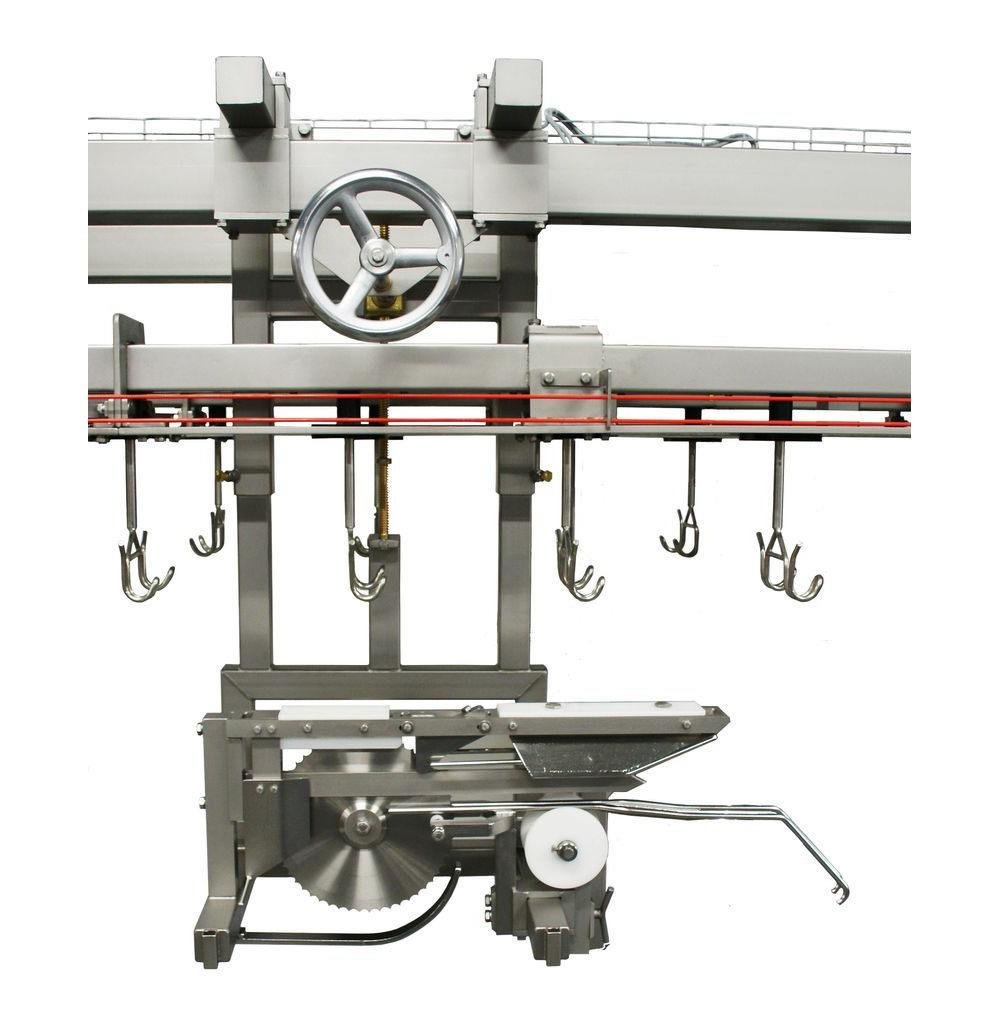

WING MODULE

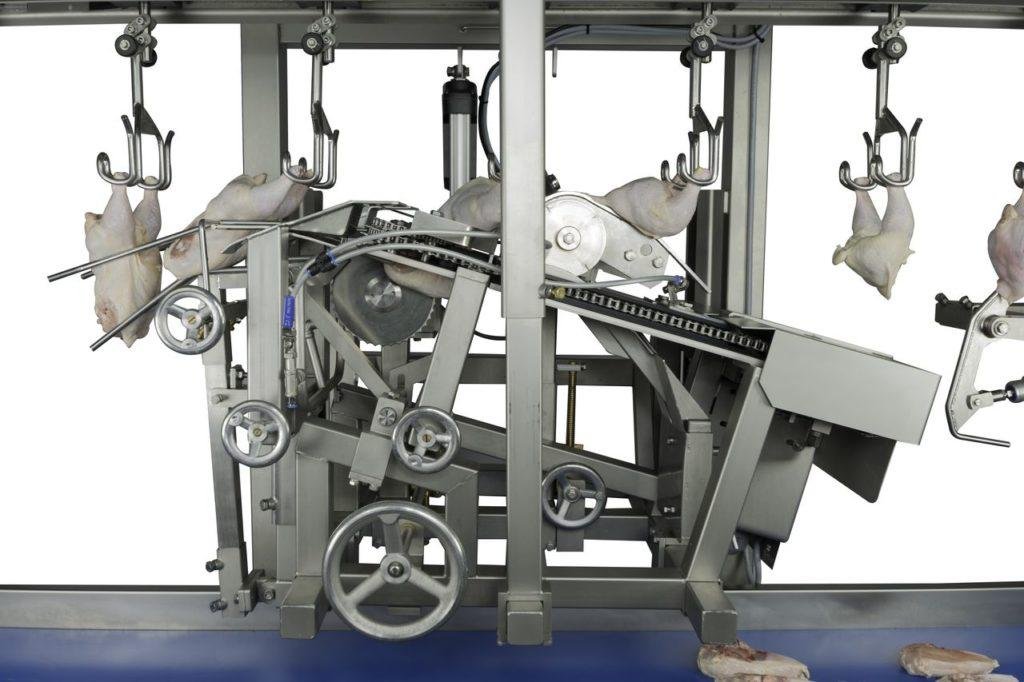

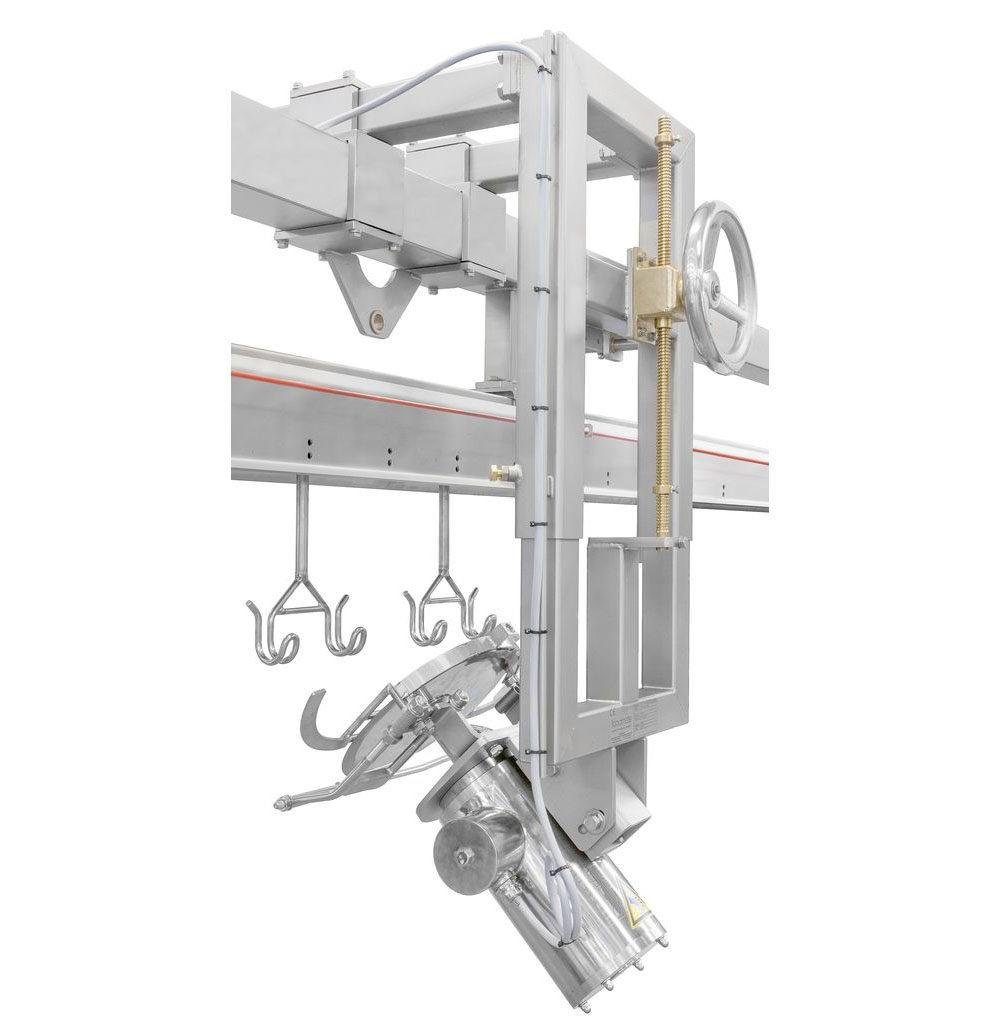

Mid Wing Cutter

-

The Foodmate Mid Wing Cutter is designed and developed to separate the mid wing piece (flapper/ median) from the wing drummette, also known as the first joint piece. The machine cuts through the center joint of the chicken wings and can be used on chickens with or without the wing tips. The chickens are transported on shackles connected to a chain which is guided by rails. With the help of a bar, the chickens are lifted and pressed against the rails, which positions the wings in the correct angle and position. The wing centers are then cut by circular blades.

The horizontal distance between the blades can be easily adjusted with the spindle. The module height is set throughout and the height of the blades can be adjusted according to the size of the chicken.

-

Allows for a maximum 6,000 birds per hour

Can be used on chickens with or without the wingtips

Separates the mid wing piece from the wing drummette

Integrates into existing frame or flex type cut up systems

Height of the blades can be adjusted according to the size of the chicken

-

Stainless steel frame and motor

Motor (IP66) power is 2 x 0,75 kW

Machine dimensions:

– Length: 728 mm

– Width: 1106 mm

– Height: 1308 mm

– Weight: approx. 151 kg

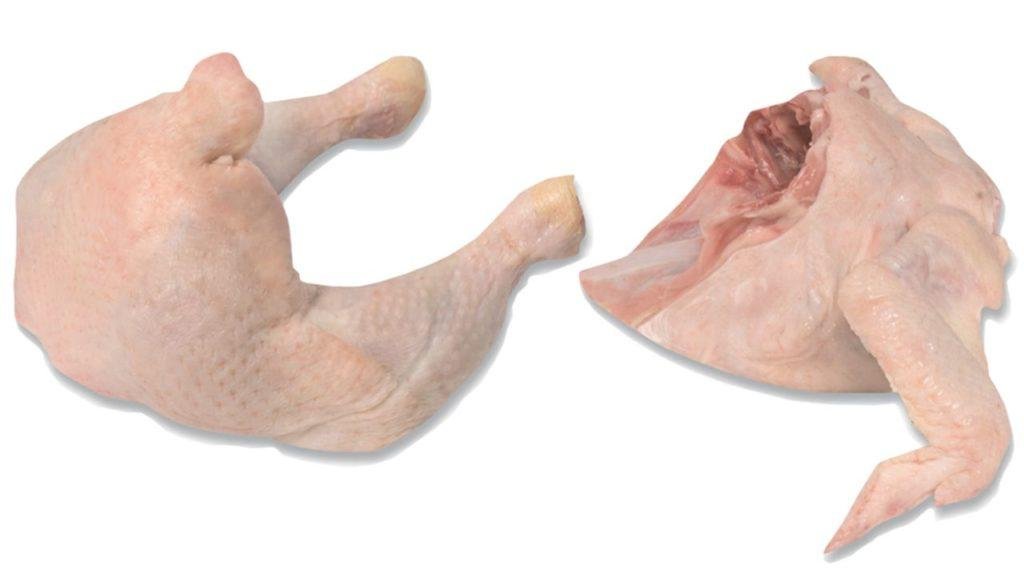

WING MODULE

Wing Cutter AFS

-

The new Foodmate AFS (All Food Service) Wing Cutter is designed to meet the latest requirements for major fast food chicken restaurants. The machine is capable of cutting both new requirements and traditional Silver Dollar style with just a minimum adjustment. The AFS Wing Cutter can be installed into most existing Cut-up lines and on a new Foodmate Food Service Cut-up System.

-

Allows for a maximum 6,000 birds per hour

-

Stainless steel frame and motor

Motor (IP66) power is 2 x 0,75 kW

Machine dimensions:

– Length: 689 mm

– Width: 1027 mm

– Height: 1515 mm

– Weight: approx. 167 kg

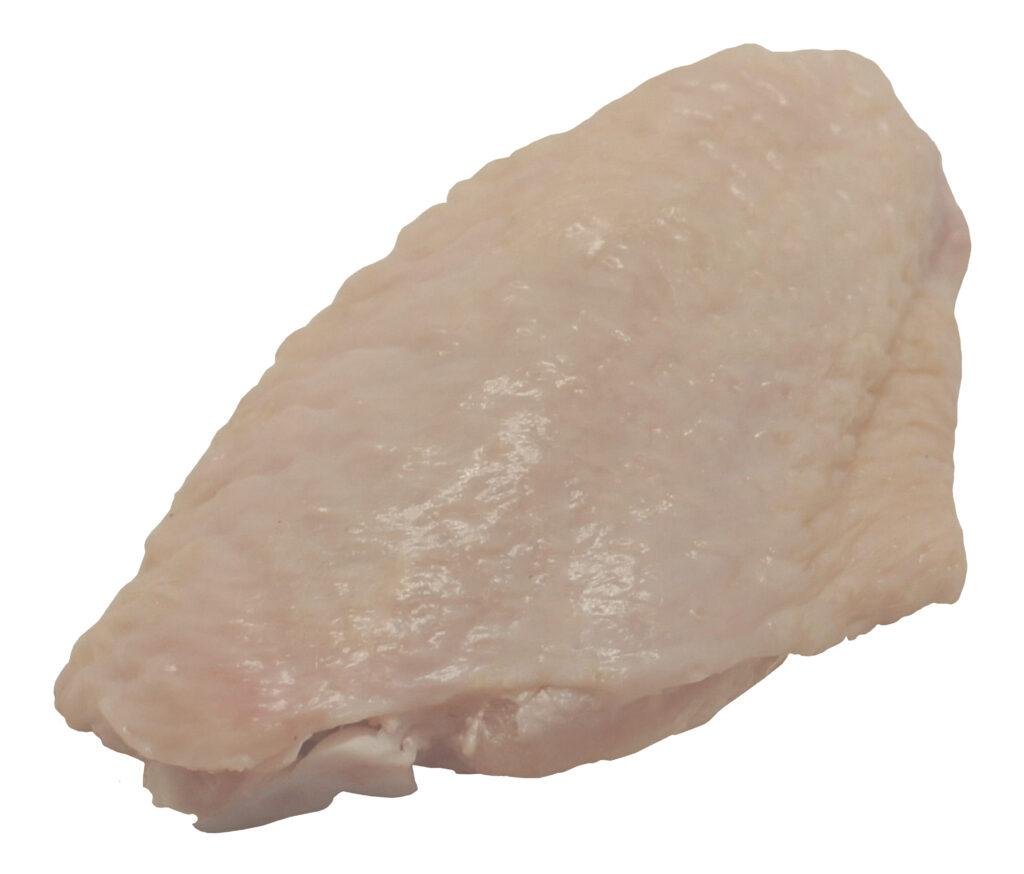

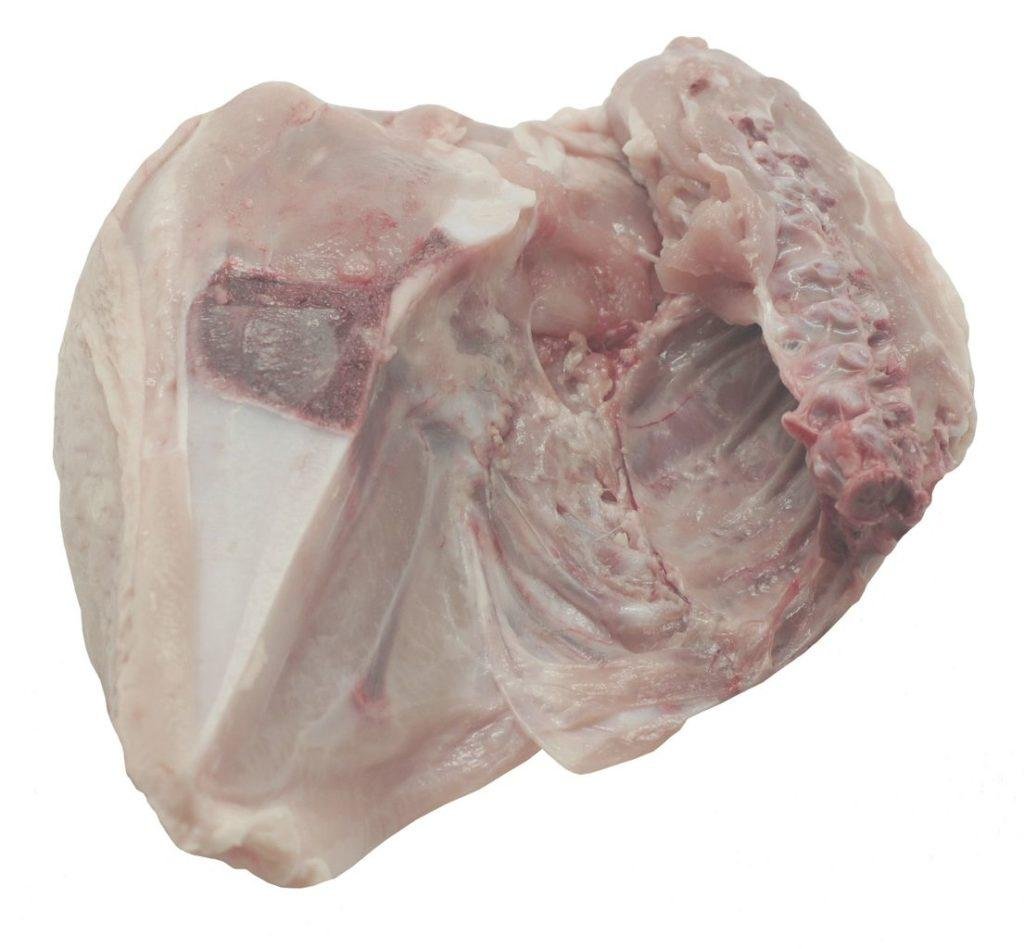

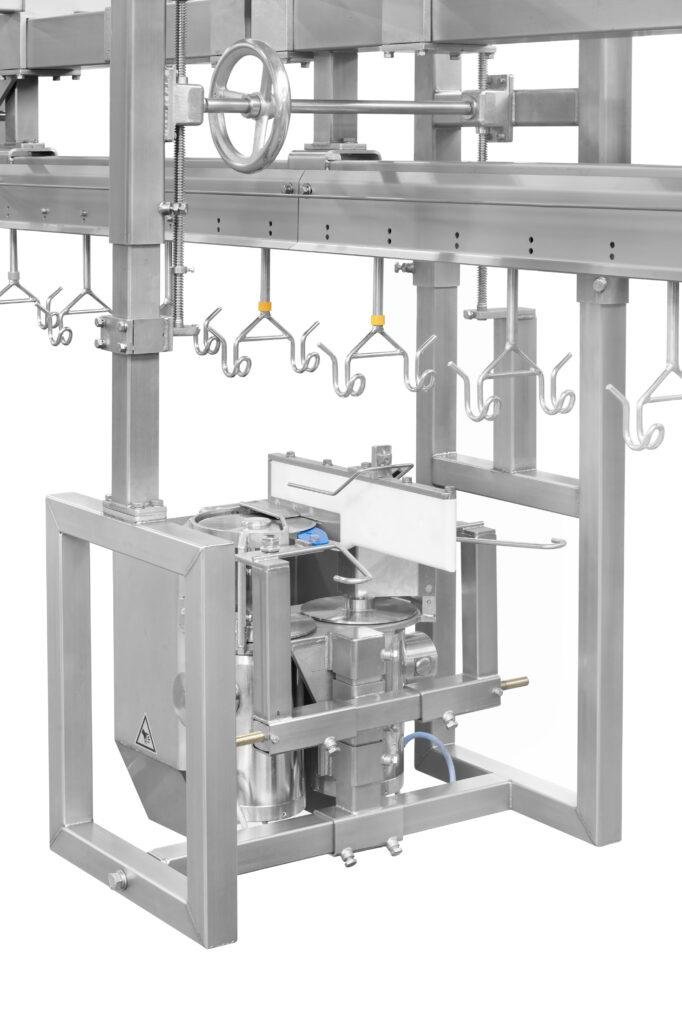

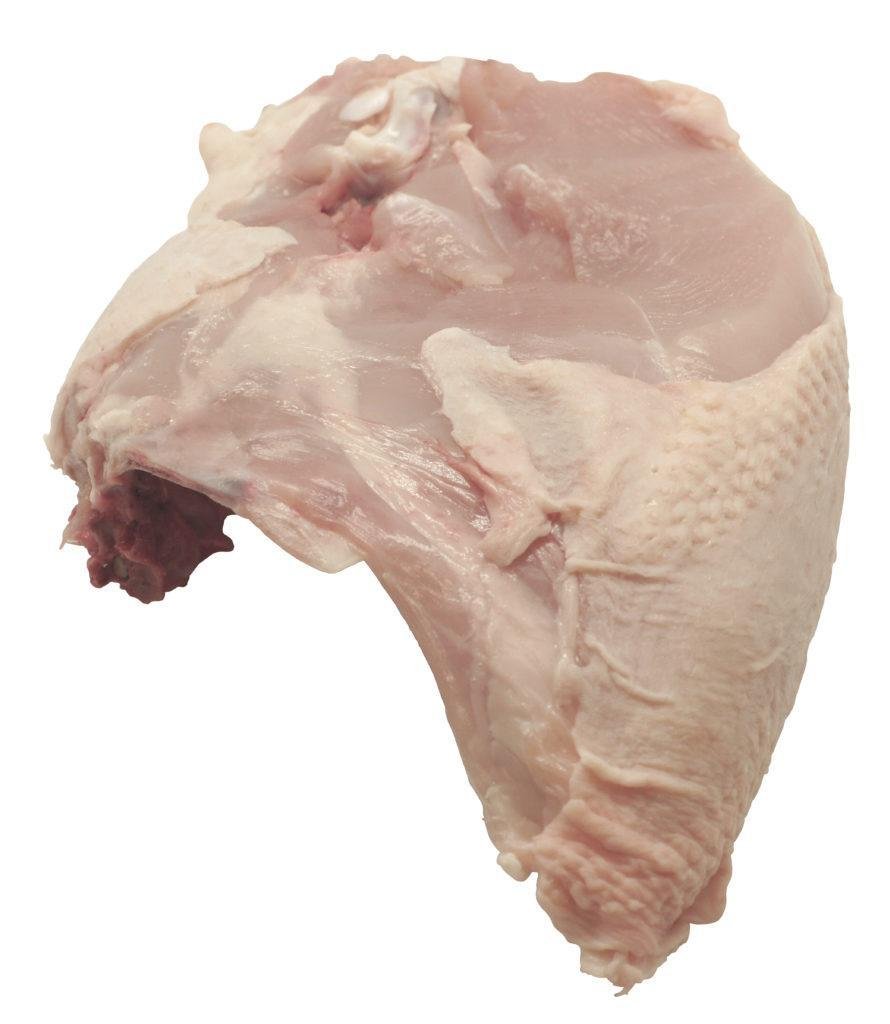

BREAST MODULE

Breast Cap Cutter

-

The Foodmate Breast Cap Cutter separates the breast cap from the back piece. The machine gives an optimal result with a minimum loss of breast meat and can be easily adjusted to various bird sizes.

The process is managed as the broilers are hanging from the shackle conveyor and are pulled over an arbor. The covers around the circular blades also work as guides for the legs, so that the broiler is positioned correctly for the cut.

The height of the machine can be adjusted to broiler sizes by rotating the spindle.

-

Allows for a maximum of 6,000 birds per hour

Requires minimal maintenance

Easy to clean

-

Stainless steel frame and motor

Motor (IP66) power is 2 x 0,75 kW

Machine dimensions:

– Length: 1055 mm

– Width: 754 mm

– Height: 949 mm

– Weight: approx. 151 kg

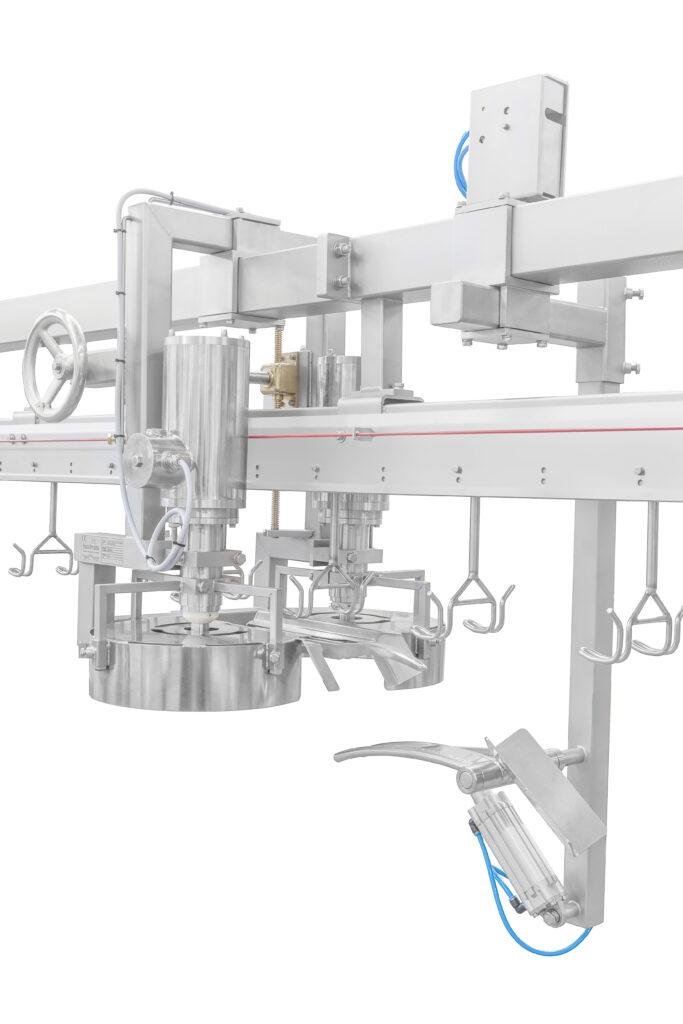

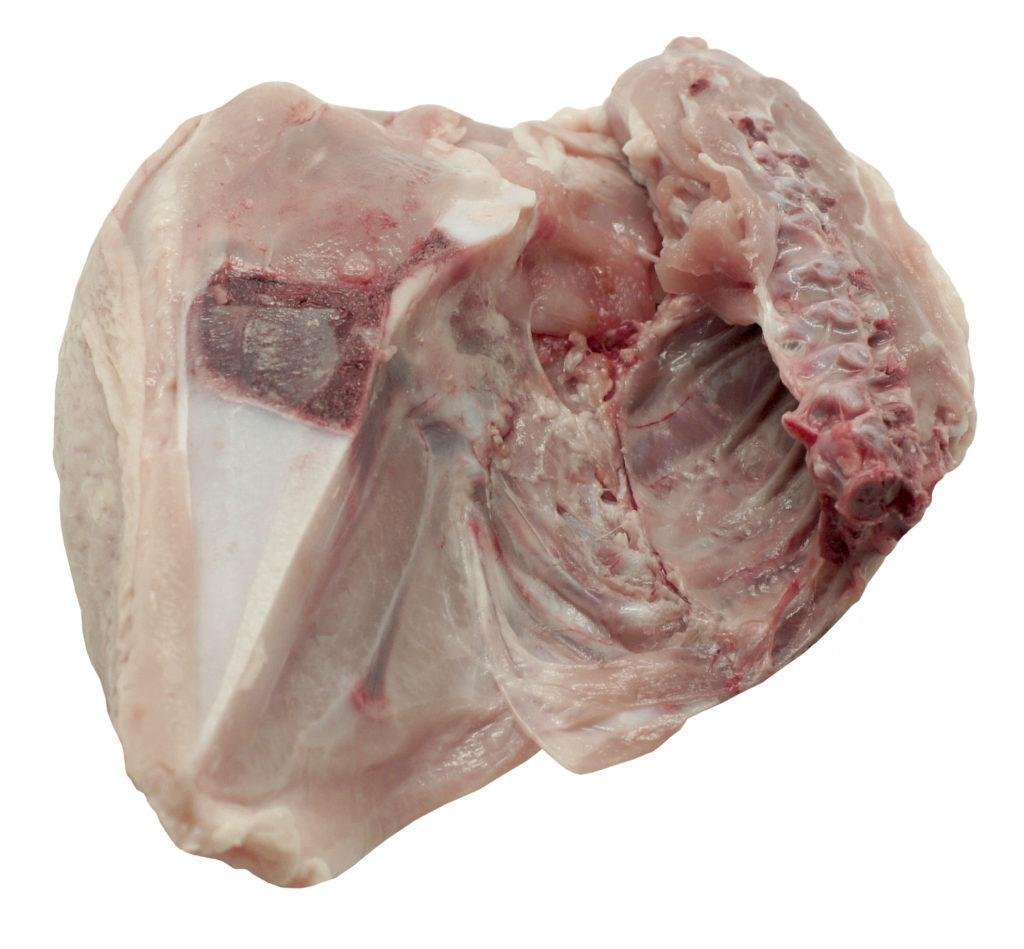

BREAST MODULE

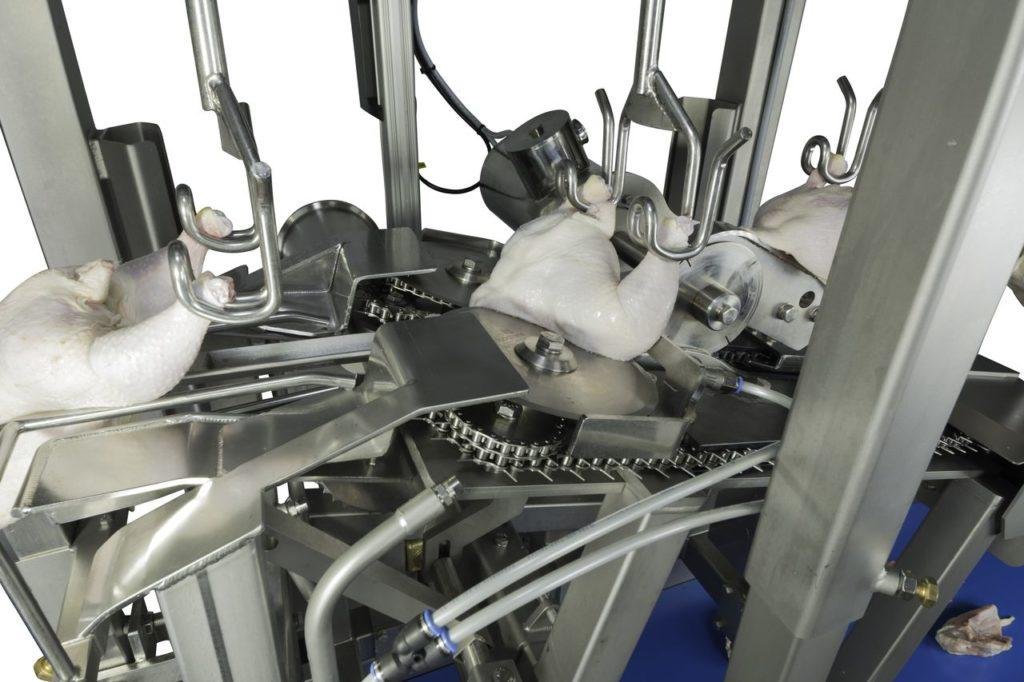

Breast Processor

-

The Foodmate Breast Processor is designed to produce split breast or whole breast with or without back. The machine has unique design features that allows for accurate cuts and minimizes the chances of birds clogging the machine.

The Breast Processor runs birds breast first. An arbour and several guidings pick up the bird and guide them into the circular blade. The breasts are then cut and transported through the machine by the pick-up chains.

-

Allows for a maximum of 6,000 birds per hour

Requires minimal maintenance

Easy to clean

-

Stainless steel frame and motor

Motor (IP66) power is 0,75 kW

Machine dimensions:

– Length: 1435 mm

– Width: 1342 mm

– Height: 1747 mm

– Weight: approx. 320 kg

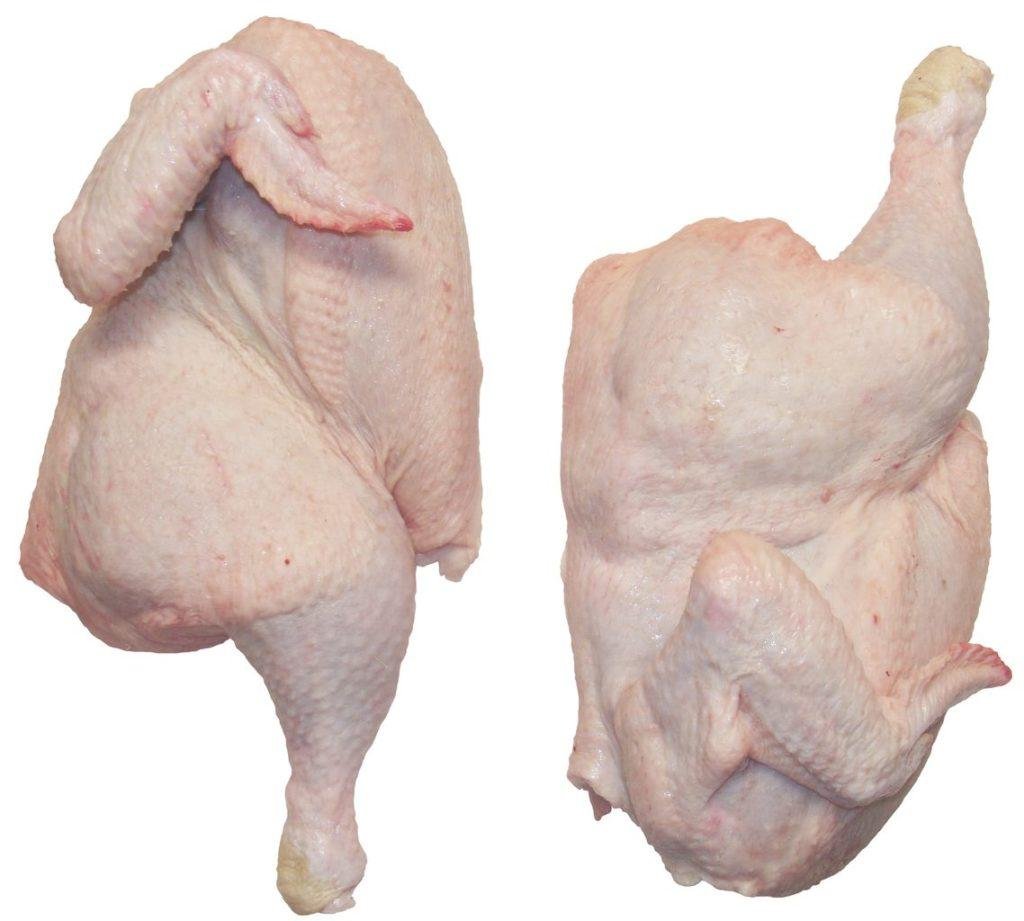

BREAST MODULE

Halving Machine

-

The Foodmate Halving Machine separates the front half from the chicken. The machine also can be used to cut off the remaining backbone piece after using the FM Breast Cap Cutter. It requires minimal maintenance and is easy to clean. The Halving Machine can be installed on current figurations or newly constructed Frame and Flex Lines.

-

Allows for a maximum of 6,000 birds per hour

-

Stainless steel frame and motor

Motor (IP66) power is 0,75 kW

Machine dimensions:

– Length: 737 mm

– Width: 680 mm

– Height: 1128 mm

– Weight: approx. 95 kg

BREAST MODULE

Halving Machine 2

-

The Foodmate Halving Machine 2 removes the breast bone from a half bird and can be used on both the 8-Piece and the 9-Piece Food Service System. This halving machine has dual blades, offering a precise horizontal cut, delivering the desired cut-out.

The lengthwise half cut chicken (done by the precutter) will run into this module, breast side first, and will be guided on the side of the hips into the module.

The Halving Machine 2 is suitable for all Cut-up systems.

-

Easy to clean

Requires minimal maintenance

Allows for a maximum of 6,000 birds per hour

-

Stainless steel frame and motor

Motor (IP66) power is 2 x 0,75 kW

Machine dimensions:

– Length: 721 mm

– Width: 670 mm

– Height: 1348 mm

– Weight: approx. 150 kg

BREAST MODULE

Cross Halving Machine

-

The Foodmate Cross Halving Machine addresses problems commonly found with single bladed front halving machines. Using two blades instead of one large blade gives a better straight cut across the hips and gives more control over the number of ribs that stay attached to the front half.

There is no need for a Pre-cutter with the Cross Halving Machine and it contains a simple construction with no belts and easy maintenance.

-

Allows for consistent and straight cuts

Cut can be adjusted to help increase leg quarter yield

Does not cut into keel tip

3 – 4 rib count on front half

Eliminates the need for a pre-cutting machine

Allows for easy adjustment and easy maintenance due to the simple construction

Integrates easily into existing frame or flex cut-up system

-

• Stainless steel frame and motor

• Motor (IP66) power is 2 x 0,75 kW

• Machine dimensions:

– Length: 882 mm

– Width: 694 mm

– Height: 882 mm

– Weight: approx. 235 kg

(incl. Bypass: 355 kg)

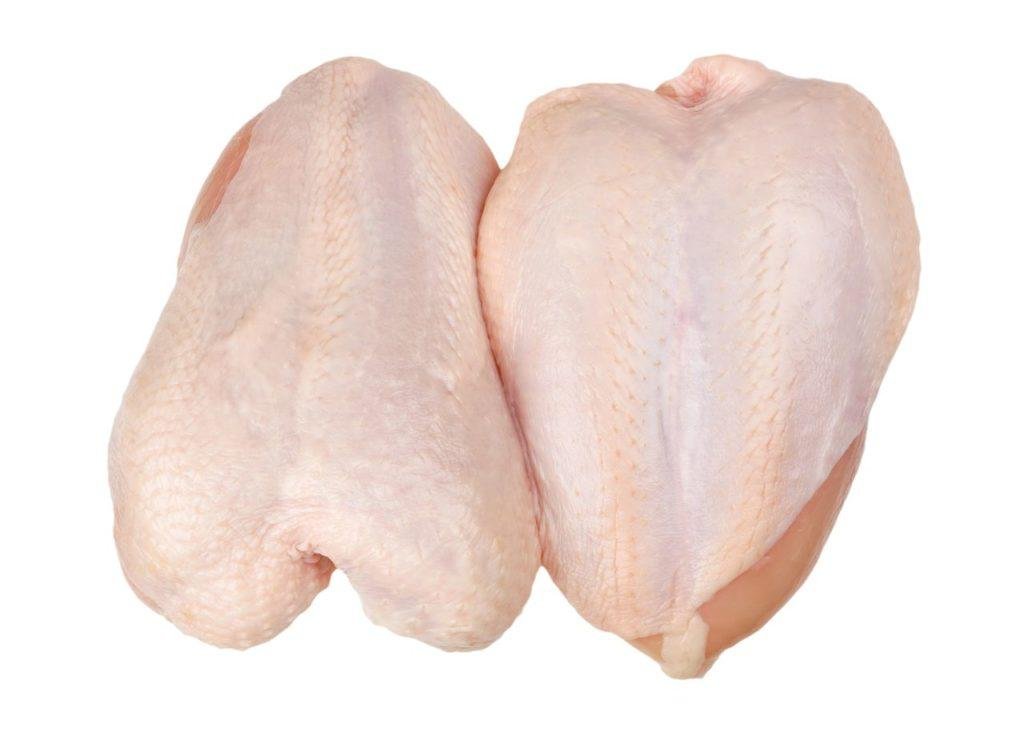

BREAST MODULE

Lengthwise Halving Machine

-

The Foodmate Lengthwise Halving Machine splits the bird into two equal length halves. The machine can be adjusted to several bird sizes. The Foodmate Lengthwise Halving Machine gives the highest accuracy to get two identical halves. It can be installed on current figurations or newly constructed Frame and Flex Lines.

-

Allows for a maximum of 6,000 birds per hour

-

Stainless steel frame and motor

Motor (IP66) power is 0,75 kW

Machine dimensions:

– Length: 981 mm

– Width: 716 mm

– Height: 1101 mm

– Weight: approx. 148 kg

BREAST MODULE

Pipistrello Cutter

-

Foodmate’s Pipistrello Cutter is designed to produce the famous pipistrello part. The module has unique design features that allows for accurate cuts and minimizes the chances of birds clogging the module. The Pipistrello Cutter is suitable for all our Cut-up lines and can be by-passed.

-

Allows for a maximum of 6,000 birds per hour

-

Stainless steel frame and motor

Motor (IP66) power is 0,75 kW

Machine dimensions:

– Length: 1055 mm

– Width: 754 mm

– Height: 949 mm

– Weight: approx. 160 kg