SPIRAL FREEZING, CHILLING & COOLING SOLUTIONS

Choose a Lomax Spiral for the rapid freezing, chilling, cooling and conveying of a wide range of products at capacities between 200 kg/hr and 10,000 kg/hr including meat, poultry, dairy, seafood, ready meals, potato products, vegetables, bakery, confectionery and pharmaceutical whether packed or unpacked in a relatively small footprint.

SPIRAL SYSTEMS

COMPACT

SPIRAL

-

Small in size but with maximum impact, the Lomax Compact Spiral delivers a one-piece unit ready to connect and operate with minimal install and commission time. For quick freezing, chilling and cooling volumes in the region of 200 kg/hr to 2,000 kg/hr of products with short to medium retention times.

-

✔️ For 200 kg/hr to in excess of 2,000 kg/hr of product

✔️ Multiple belt width, configuration and material options

✔️ Branded major components for maximum reliability

✔️ Ultra-efficient dual-flow air system with variable control options

✔️ For freezing and cooling packed and unpacked product

✔️ British bespoke design and manufacture

-

✔️ Spiral belt options include various widths, different infeed and exit orientations, all stainless steel, all plastic or hybrid cross of stainless steel and plastic materials according to application and preference

✔️ Stainless steel structure hygienically designed to ensure quick cleaning and max uptime

✔️ Branded main components ensuring highest quality and reliable backup and spares

✔️ Various levels of ongoing service support offered post warranty

SINGLE DRUM

SITE BUILT SPIRAL

-

When medium to large capacities need to be handled in a spiral system with a relatively small footprint, then the Lomax site built single drum spiral is ideal. A bespoke design ensures a perfect fit into any factory layout, whether there are footprint or height limits, Lomax will design accordingly. Typically for capacities in the region of 1,000 kg/hr to 6,000 kg/hr for the freezing and cooling of a wide variety of packed and unpacked products.

-

✔️ For 1,000 kg/hr to in excess of 6,000 kg/hr

✔️ Multiple belt width, configuration and material options

✔️ Branded major components for maximum reliability

✔️ Highly efficient airflow with variable control options

✔️ For freezing and cooling packed and unpacked product

✔️ British bespoke design and project management

✔️ British manufacture

-

✔️ Spiral belt options include various widths, different infeed and exit orientations, all stainless steel, all plastic or hybrid cross of stainless steel and plastic materials according to application and preference

✔️ Stainless steel structure hygienically designed to ensure quick cleaning and max uptime

✔️ Branded main components ensuring highest quality and reliable backup and spares

✔️ Various levels of ongoing service support offered post warranty

TWIN DRUM

SITE BUILT SPIRAL

-

The twin drum spiral provides ultra-flexibility on large volumes, typically between 3,000 kg/hr and 10,000 kg/hr of packed and unpacked product, ideal for medium to long retention times, low in and out or high in and out belt directions and multiple entry and exit positions. The twin drum (also called double drum) spiral orientation will also allow various footprint formats such as long rectangular where factory width is tight or a square design, both styles allowing maximum roof height to be utilised if needed.

-

✔️ Typically for 3,000 kg/hr to in excess of 10,000 kg/hr

✔️ Large volumes of small products or for larger and longer freeze time products

✔️ Multiple belt width, configuration and material options

✔️ In low and out low or in high and out high configurations

✔️ Branded major components for maximum reliability

✔️ Highly efficient airflow with variable control options

✔️ For freezing and cooling packed and unpacked product

✔️ British bespoke design and project management

-

✔️ Spiral belt options include various widths, different infeed and exit orientations, all stainless steel, all plastic or hybrid cross of stainless steel and plastic materials according to application and preference

✔️ Stainless steel structure hygienically designed to ensure quick cleaning and max up time

✔️ Branded main components ensuring highest quality and reliable backup and spares

✔️ Various levels of ongoing service support offered post warranty

DIRECT DRUM

DRIVE SPIRAL

-

Where product placement on the belt becomes critical and operating conditions are likely to cause a regular lo-tension spiral to require excessive cleaning to maintain low tensions, then the drum driven spiral should be considered. With positive drum to belt engagement the system maintains a lower tension condition that would be well suited to situations where product debris increases belt-to-track friction, such as high flour, high grease or sugary applications.

-

✔️ For 200 kg/hr to in excess of 2,000 kg/hr

✔️ Multiple belt width, configuration and material options

✔️ Branded major components for maximum reliability

✔️ Highly efficient airflow with variable control options

✔️ For freezing and cooling packed and unpacked product

✔️ British bespoke design and project management

-

✔️ Spiral belt options include various widths, different infeed and exit orientations, all stainless steel, all plastic or hybrid cross of stainless steel and plastic materials according to application and preference

✔️ Stainless steel structure hygienically designed to ensure quick cleaning and max uptime

✔️ Branded main components ensuring highest quality and reliable backup and spares

✔️ Various levels of ongoing service support offered post warranty

DIRECT EDGE

DRIVE SPIRAL

-

For maximum flexibility in direct belt drive designs, the external edge drive solution provides a low tension spiral that eliminates the need for a central drum and provides the ability to run up and down belt directions in the same spiral stack, whether circular format or oval track format. With the removal of the central drive drum that conventional lo-tension spirals have, space can be made for an evaporator or other equipment that reduces the overall footprint of the spiral.

-

✔️ For 200 kg/hr to in excess of 6,000 kg/hr

✔️ Multiple belt width, configuration and material options

✔️ Branded major components for maximum reliability

✔️ Highly efficient airflow with variable control options

✔️ For freezing and cooling packed and unpacked product

✔️ British bespoke design and project management

-

✔️ Spiral belt options include various widths, different infeed and exit orientations, all stainless steel, all plastic or hybrid cross of stainless steel and plastic materials according to application and preference

✔️ Stainless steel structure hygienically designed to ensure quick cleaning and max up time

✔️ Branded main components ensuring highest quality and reliable backup and spares

✔️ Various levels of ongoing service support offered post warranty

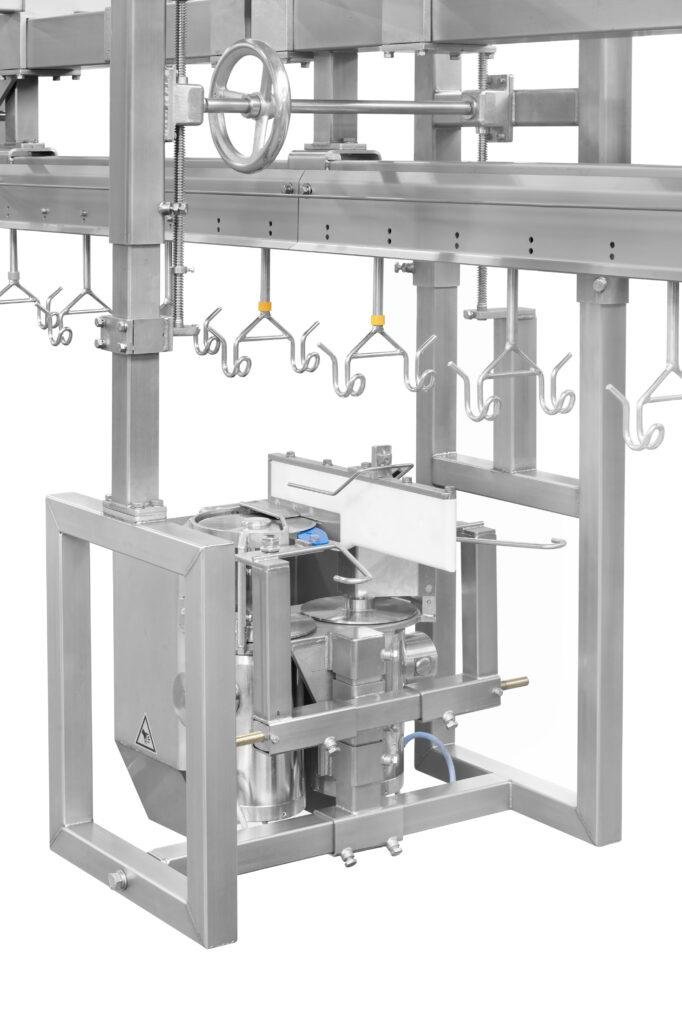

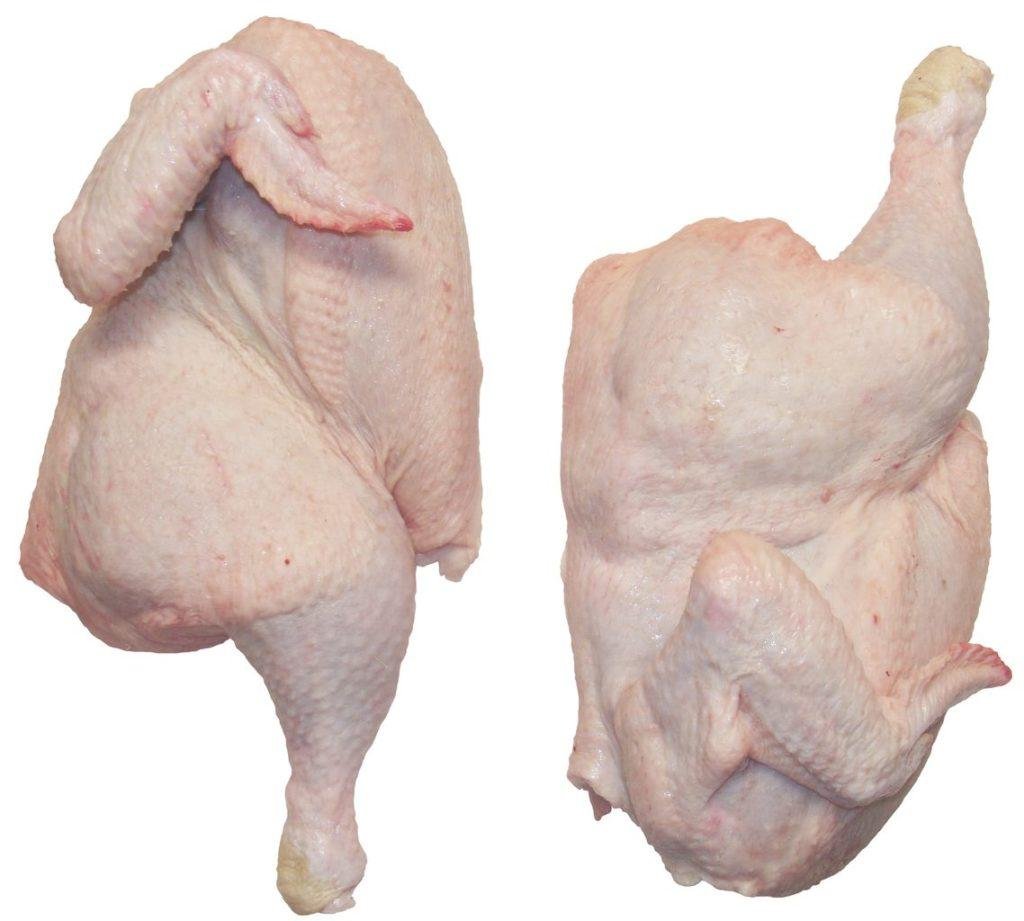

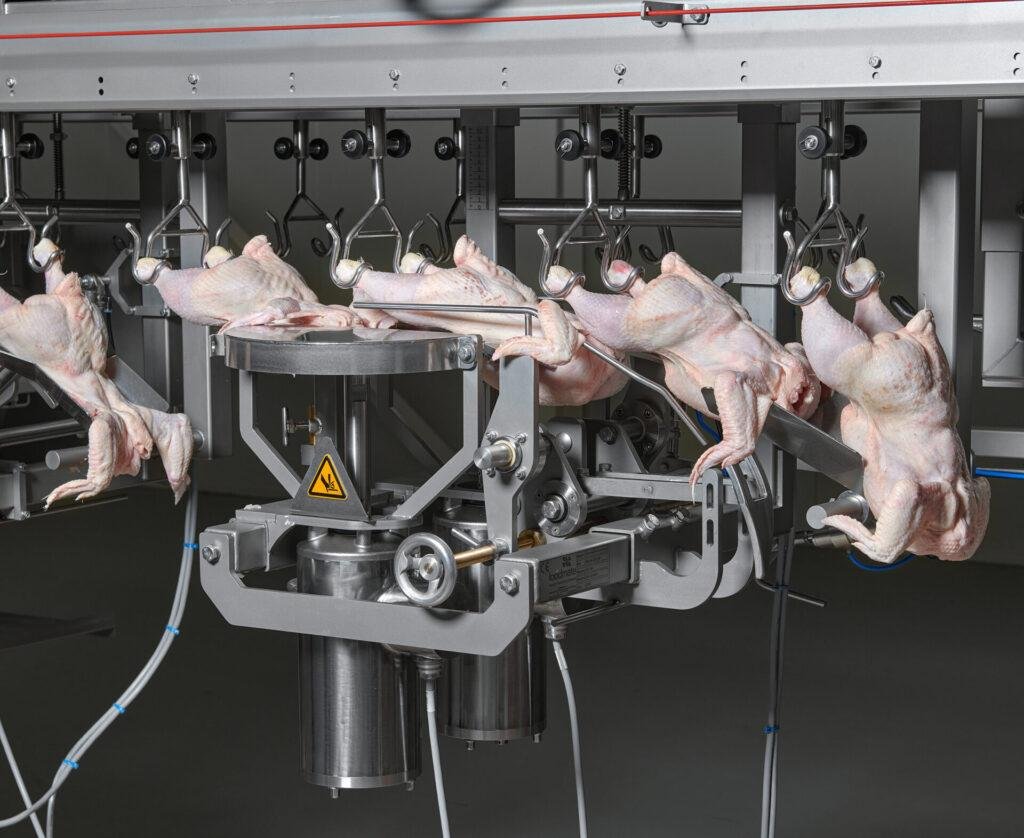

BREAST MODULE

Halving Machine 2

-

The Foodmate Halving Machine 2 removes the breast bone from a half bird and can be used on both the 8-Piece and the 9-Piece Food Service System. This halving machine has dual blades, offering a precise horizontal cut, delivering the desired cut-out.

The lengthwise half cut chicken (done by the precutter) will run into this module, breast side first, and will be guided on the side of the hips into the module.

The Halving Machine 2 is suitable for all Cut-up systems.

-

Easy to clean

Requires minimal maintenance

Allows for a maximum of 6,000 birds per hour

-

Stainless steel frame and motor

Motor (IP66) power is 2 x 0,75 kW

Machine dimensions:

– Length: 721 mm

– Width: 670 mm

– Height: 1348 mm

– Weight: approx. 150 kg

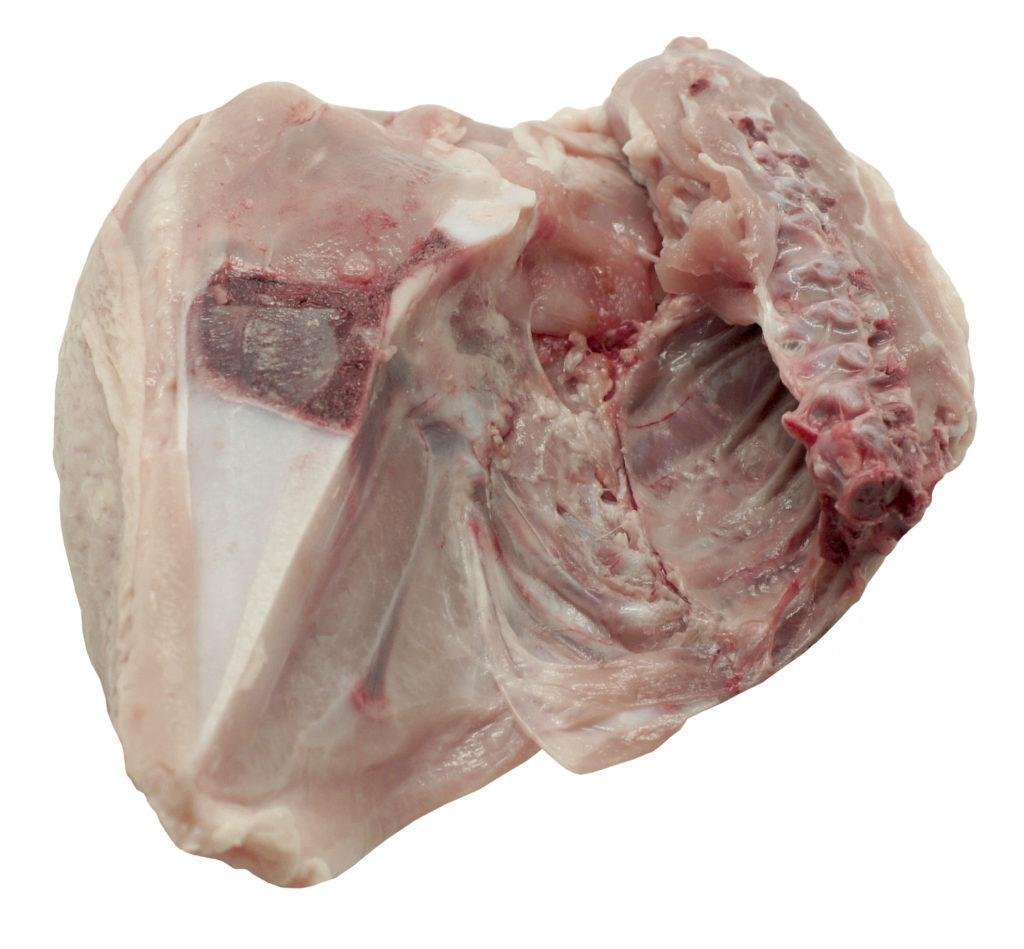

BREAST MODULE

Cross Halving Machine

-

The Foodmate Cross Halving Machine addresses problems commonly found with single bladed front halving machines. Using two blades instead of one large blade gives a better straight cut across the hips and gives more control over the number of ribs that stay attached to the front half.

There is no need for a Pre-cutter with the Cross Halving Machine and it contains a simple construction with no belts and easy maintenance.

-

Allows for consistent and straight cuts

Cut can be adjusted to help increase leg quarter yield

Does not cut into keel tip

3 – 4 rib count on front half

Eliminates the need for a pre-cutting machine

Allows for easy adjustment and easy maintenance due to the simple construction

Integrates easily into existing frame or flex cut-up system

-

• Stainless steel frame and motor

• Motor (IP66) power is 2 x 0,75 kW

• Machine dimensions:

– Length: 882 mm

– Width: 694 mm

– Height: 882 mm

– Weight: approx. 235 kg

(incl. Bypass: 355 kg)

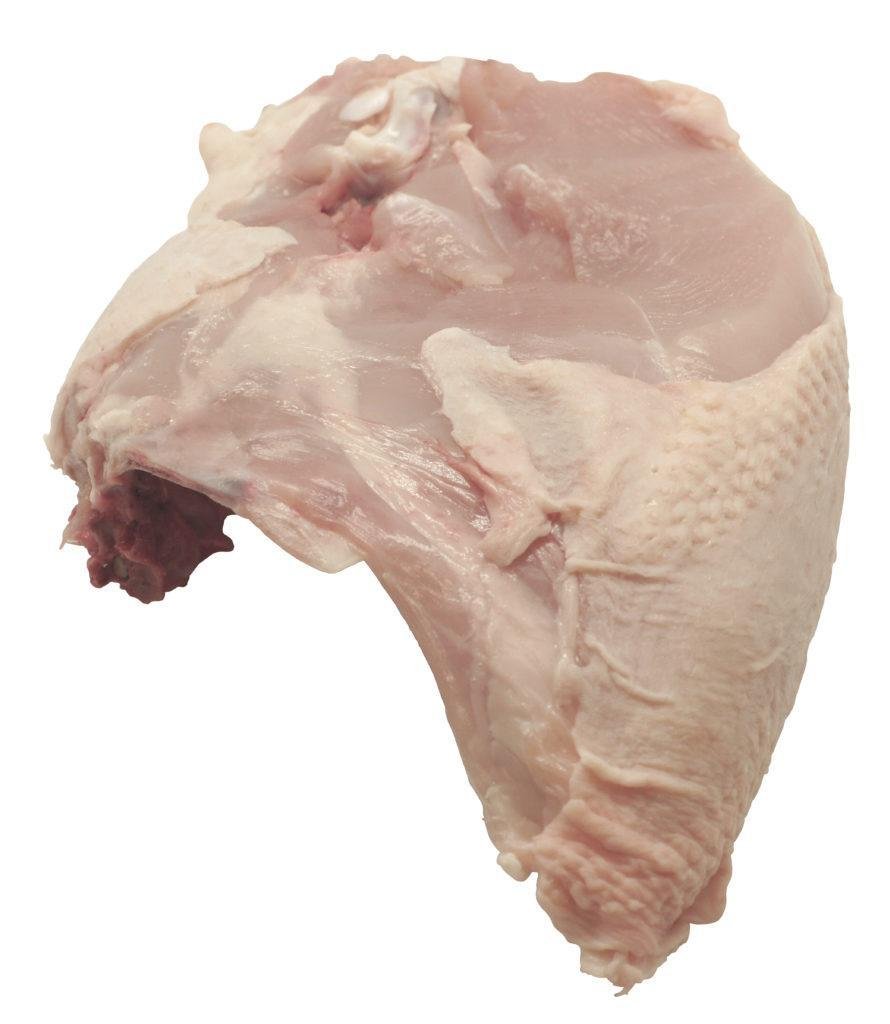

BREAST MODULE

Lengthwise Halving Machine

-

The Foodmate Lengthwise Halving Machine splits the bird into two equal length halves. The machine can be adjusted to several bird sizes. The Foodmate Lengthwise Halving Machine gives the highest accuracy to get two identical halves. It can be installed on current figurations or newly constructed Frame and Flex Lines.

-

Allows for a maximum of 6,000 birds per hour

-

Stainless steel frame and motor

Motor (IP66) power is 0,75 kW

Machine dimensions:

– Length: 981 mm

– Width: 716 mm

– Height: 1101 mm

– Weight: approx. 148 kg

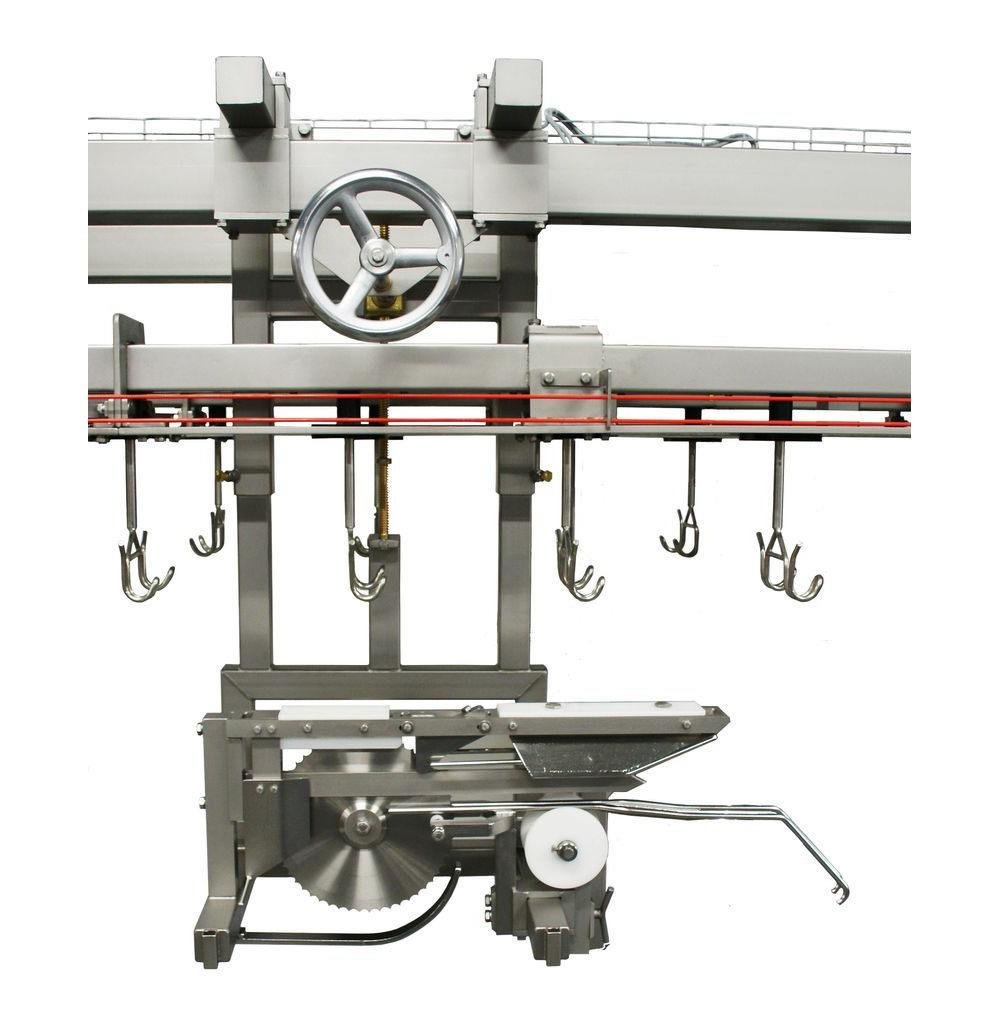

BREAST MODULE

Pipistrello Cutter

-

Foodmate’s Pipistrello Cutter is designed to produce the famous pipistrello part. The module has unique design features that allows for accurate cuts and minimizes the chances of birds clogging the module. The Pipistrello Cutter is suitable for all our Cut-up lines and can be by-passed.

-

Allows for a maximum of 6,000 birds per hour

-

Stainless steel frame and motor

Motor (IP66) power is 0,75 kW

Machine dimensions:

– Length: 1055 mm

– Width: 754 mm

– Height: 949 mm

– Weight: approx. 160 kg