FOODMATE OPTI DRUMSTICK DEBONER

6000 drumsticks per hour!

Foodmate developed the OPTI Drumstick Deboner in response to the increasing demand and production of deboned drumstick meat. The machine is designed to run 6000 drumsticks per hour and only requires two loaders due to the Easy Load product shackle.

FOODMATE DARK MEAT DEBONING SYSTEMS

OPTI DRUMSTICK DEBONER

After loading the drumsticks, the first process is the automatic Pre-Cutter where a cam operated arm and blade make a cut along the side of the bone. Making a pre-cut helps prevent bone breakage during deboning and makes it easy for the trimmers to inspect and trim the meat without first having to cut it open.

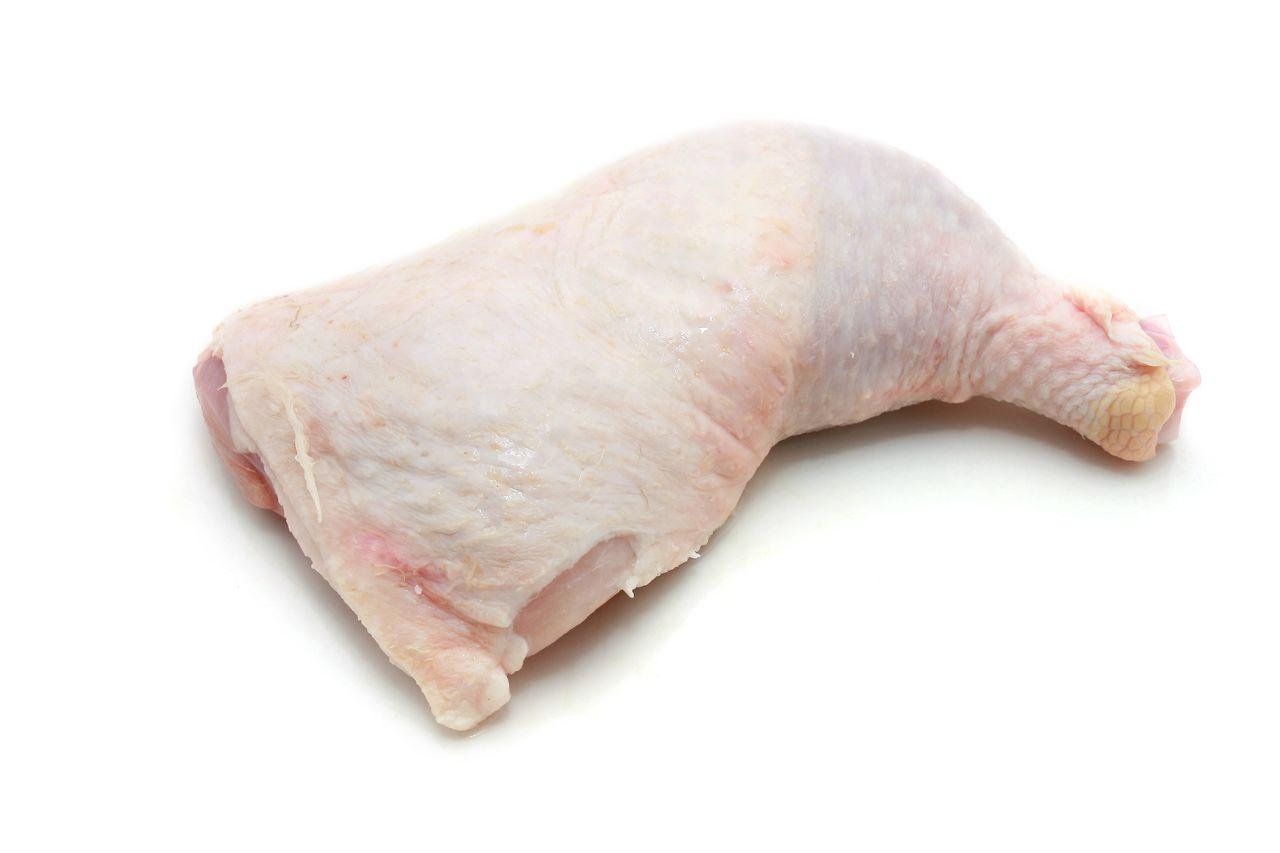

INITIAL PRODUCT

FINAL PRODUCT

OPTIMAL YIELDS DELIVERED WORLDWIDE

Compact, efficient and flexible.

The next process after the Pre-Cutter is cutting the tendons. The tendons are cut as the drumstick rotates 360 degrees along a series of circular blades. To ensure that the pin bone stays with the bone during the deboning process, Foodmate developed a special device that masks the tendon which connects to the pin bone during the tendon cutting process.

After all the tendons are cut, an innovative scraper design pulls the meat off the bone providing the highest yield, meat quality and minimal bone content.

FOODMATE OPTI DRUMSTICK DEBONER

Exceptional yields. No bones about it.

Foodmate developed the OPTI Drumstick Deboner in response to the increasing demand and production of deboned drumstick meat.

-

✔️ Easy product loading

✔️ No bone fragmentation in the meat

✔️ Same footprint as OPTI Thigh Deboner

✔️ Machine can process different weights

✔️ Drumsticks deboning, with and without skin

✔️ An excellent end-result in combination with high efficiency

✔️ High speed automatic deboning of drumsticks to 6000 pieces per hour

✔️ Utilizes the same mechanical concepts as the highly successful OPTI Thigh Deboner

✔️ Latest generation machines feature enhanced safety features such as integrated safety PLCs and DC injection brakes

-

Capacity: 100 drumsticks per minute

Construction: Stainless steel 304 and FDA approved synthetics

Power consumption: 3,5 kW

One main connection to control panel

Cleaning: Designed for optimal cleaning to meet hygienic standards.

Machine Dimensions

Length: 6230 mm

Width: 1800 mm

Height: 2145 mm

Weight: approx. 2830 kg