Key benefits

Optimized yield

Unparalleled accuracy

Modular belt

Adding options

User-friendly software interface

MATRIX P production reports

Extremely hygienic, easy to clean

Service

Low noise

Double infeed

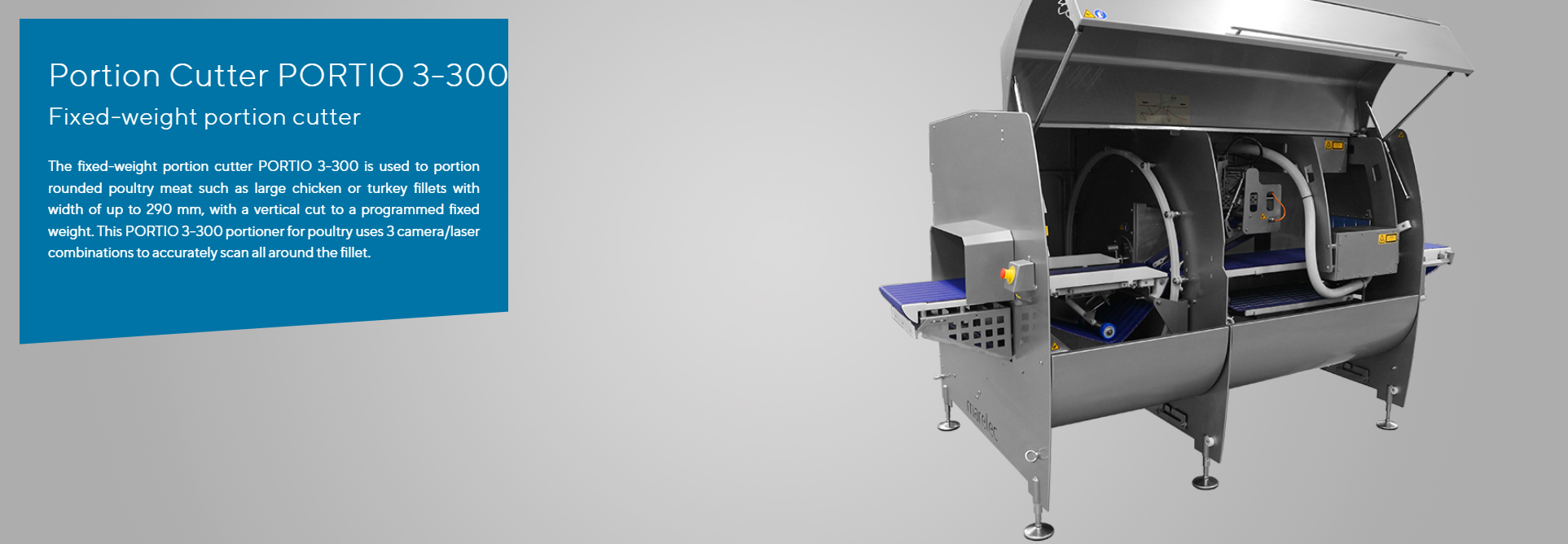

The PORTIO 3-300 fixed-weight portion cutter for poultry uses a top camera combined with lateral side cameras to scan the volume of larger more rounded chicken or turkey fillets. Bolt-on options are available to adapt the fixed weight portioning machine over the operating life of the portioner in accordance with the evolution of your applications and processes.

Specifications

Lanes: 1

Cameras: 3

Belt width: 305 mm / 12 inches

Max. product dimensions: 800 x 290 x 150 mm / 31.5 x 11.5 x 6 inches

Max. cutting rate: 14 cuts/sec *

Machine dimensions: 3435 x 1475 x 1711 mm / 135 x 58 x 67 inches

Machine net weight: 1270 kg / 2799 lb

Optimized yield

The PORTIO software for the portion cutter always calculates the cuts so as to leave zero waste, and maximize the yields. Conditional programs are possible for increased yields. Combinations of fixed thickness and various fixed weights allow portioning for maximum yield for all poultry applications.

Unparalleled accuracy

3 sets of laser camera, one on the top and 2 on the sides perfectly scan more rounded chicken or turkey fillets. This transforms the shape of the poultry product into a 3D model. As it knows the density of the meat, the intelligent software of the portioning machine instantly calculates where to cut the product to obtain the target weights.

Modular belt

The portion cutter has automatic stretch compensation which guarantees optimum accuracy over the years, using the same belt. The unique belt surface is specially designed for poultry products and will keep the products in place and prevents them from moving during portioning.

Adding options

Specially designed options can be bolted on to the portioner at any later stage for specific applications. A laser line can be projected on the infeed belt to indicate to the operator the correct placement of the chicken fillets. The density scale compensates for variation in injected poultry products. The Automatic Product Holder prevents the crustfrozen chicken fillets from moving during portioning. The BackHolder holds the last portion upwards. The retractable outfeed belt allows the head to be separated or the tail to be trimmed and can be combined with a blow-off system.

User-friendly software interface

Intuitive programming of cutting patterns and fast and easy fine-tuning of the programs to get the maximum yields. The cutting pattern is shown on the screen along with details of the thickness and weight of each poultry portion.

MATRIX P

The MATRIX P software collects all production data from the PORTIO poultry cutting machine and allows production reports to be generated. MATRIX P enables users to remotely take programs offline and monitor the status of the poultry slicer using an event log.

Extremely hygienic, easy to clean

The portion cutter complies with the most stringent hygiene standards. The open structure of the portioning machine for poultry allows it to be fully cleaned using a pressure washer and disinfected on the inside and outside. A CIP (Cleaning In Place) system rinses the belts. All cabinets with electrics and electronics have a unique drying system to prevent the build-up of condensation. Belts can be removed with a quick release, without the need for tools.

Service

The portion cutter can be connected to the internet, allowing the status of the poultry slicer to be diagnosed from a remote service point.

Low noise

Operators appreciate the good working environment around the PORTIO thanks to its low noise levels.

Double infeed

The infeed consists of two separate infeed conveyors to reduce the impact of placing a heavier piece of meat while still scanning the previous primal.

MORE INFORMATION: